Product Handling Solutions for Bakery Production

Maximize Throughput With Automated Lane Balancing

Product Handling solutions use vision technology for Automatic Lane Balancing to ensure that packaging machines are fed by a continuous flow of evenly laned products. Vision-based lane balancing solutions offer manufacturers of baked goods a cutting-edge technology to optimize their production processes. This automation not only enhances productivity but also minimizes waste, improves product quality, and reduces the need for manual intervention. With vision-based lane balancing solutions from KPM, manufacturers of baked goods can achieve greater efficiency, consistency, and accuracy in their production operations.

Features

- Compatible with all types of baggers and bulk packers

- Flexible capabilities (in terms of number of lanes, type of products, size of products)

- No gates or moving parts that can cause production jam-ups or damage

- Low maintenance cost

- Compact footprint and easy integration with existing lines

Benefits

- Labor saving (even when not paired with an inspection/rejection system)

- Maximized throughput of packing machines

- No more manual handling of products

- No damage to products

Applications

Any baked goods that require precise placement, alignment, and spacing as it travels along the production line can greatly benefit from vision-based lane balancing solutions.

Ensuring Success Downstream

Vision-based lane balancing solutions are recommended for a wide range of baked goods, particularly products that require precise positioning and alignment on the production line. For example, bread loaves, rolls, and buns can benefit from this technology as it ensures uniform spacing and alignment ahead of packaging. Similarly, cakes, pastries, and cookies can benefit from vision-based lane balancing solutions to maintain proper positioning and prevent any deformities or misalignment during the production process. Additionally, delicate items such as macarons or cream-filled pastries can be accurately positioned and transported without damage or distortion.

Products that Typically Benefit from Lane Balancing:

- Bun, Bagel, English Muffin

- Hotdog, Ciabatta

- Bagel Thin, Sandwich Thin

- And more...

Common System Configurations

Communication Throughout the Process

Vision-Based Lane Balancing

How It Works

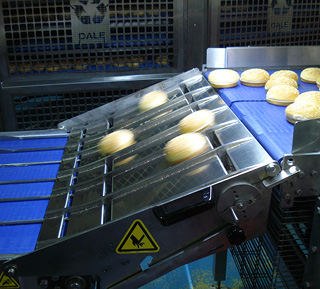

The EyePro Laner System is designed to automatically direct a flow of randomly distributed products into evenly balanced lanes on high speed bakery lines.

Understanding the Mechanisms

The system uses the latest Vision and Advanced Motion Control Technology to control a series of modular conveyors, one corresponding to each lane. Based on product distribution information, extracted and processed by the integrated Vision System, the Laner automatically adjusts the speed of each individual conveyor, guaranteeing a constant optimization and balancing of the product flow across the lanes.

With the same system, it is possible to lane different products into different number of lanes, by simply adjusting the guides on the chute and selecting different product models on the user interface.

If you combine Product Inspection and Product Handling, you will be able to measure and check your products, reject the faulty ones, lane the good ones and optimize their flow to the packaging machines.

Working principle, modules, and operation of the EyePro Laner are shown and explained in this video.

With our Product Handling Solutions, you will benefit from automatic products laning and balancing, reduction of manual product handling, maximization of line throughput and labour and cost saving. Take a look at the EyePro Laner in action on one of our Customers lines in the following video!

Configurations & Modules

In the dynamic landscape of baked goods manufacturing, KPM's vision-based lane balancing system offers a versatile range of configurations designed to optimize efficiency, precision, and quality control ahead of packaging.

Line Configurations

- Line width: from 600mm up to 1.000mm (24" - 40")

- In-feed: Straight or 90°

- Product throughput: from 300 pcs/min up to 1.000 pcs/min

- Product type and lane number: one laning system can lane different products into different number of lanes

System Modules

- Accumulation conveyor module

- Laning conveyor module

- Laning chute

- Out-feed conveyor (optional)

- Vision System used for product flow monitoring

- Motion Control Unit

Lane Balancing Software

The EyePro Laner solution features a proprietary Automatic Lane Balancing Software specifically designed for baking manufacturers.

Through the touch screen interface, the user can interact with the system, observe its functioning, and receive information such as the throughput or the product distribution across the lanes.

Specifications

Resources

We've highlighted a few knowledge center resources here to help you understand the product better. Please also visit our Knowledge Center for additional information and downloads, and don't forget that our team is always happy to answer any questions you have.