TheiaVu® E-Series Offline Vision System for Bakeries

Simple, Objective Measurement Solution for Bakeries

TheiaVu® E-Series is an offline vision system that provides objective measurements to ensure product consistency and quality. Simply place the product on the moving conveyor and product attributes can be measured objectively and consistently with minimal operator intervention. The system can be set up to inspect a range of products based on the product size and height, including cookies, buns, bread, pretzels, muffins, etc.

TheiaVu® E-Series is simple to use and replaces manual measurement and data collection. With this single tool, you can collect color, height, diameter, and many other measurement features for your product. Additionally, the data can be used with online vision systems to set and verify product specifications.

Features

Powerful: Quantify product features difficult to measure manually.

Simple: Easy-to-use operator interface.

Versatile: Can be used in lab or production areas. Washdown version available.

Flexible: Validate product features and collect measurements at various stages of development.

Benefits

- Perform quality checks faster and with better repeatability

- Know more about your product compared to manual methods

- Ensure consistent product quality between batches, shifts, and sites

- Cost savings through reduced labor and waste

- Brand protection

- Save time with reporting, all results are saved & organized

- Achieve competitive advantages

Applications

Used in the lab or at-line in your bakery, TheiaVu® E-Series systems produce critical measurement data for pre-baked doughs, production samples and final products for quality and process control.

MEASURING QUALITY WHERE IT MATTERS

Pre-Bake: Inspect dough before baking to define key attributes.

R&D: Objectively profile new products to define product specification. Compare and contrast different recipes for products to optimize product quality.

Detailed Feature Measurements: Obtain objective data to help determine the repeatability tolerances of your production process.

Quality Control: Before packaging, inspect final products for quality control.

E-Series Models

Common System Configurations

Communication Throughout the Process

Vision-Based Lane Balancing

How It Works

TheiaVu® vision systems use a selection of high-speed cameras, a laser, and imaging software to detect and measure objects as they move along the built-in conveyor belt.

Compact Machine Vision for Quality Control

Our proprietary BakeSpect™ software and measurement algorithms can determine the size, shape, color, or composite measurement of any object and convert this information into standard units for quality control purposes. Results are displayed in real-time and data for every object is saved for future analysis and reporting.

To Inspect a Product:

- Power on the system

- Select the desired product model using built-in operator interface

- Place the object on the moving conveyor belt

- Instantly view the results on-screen

You can continuously feed multiples of the same product onto the belt without resetting the system and all data will be saved. There is no need for manual note taking or spreadsheets.

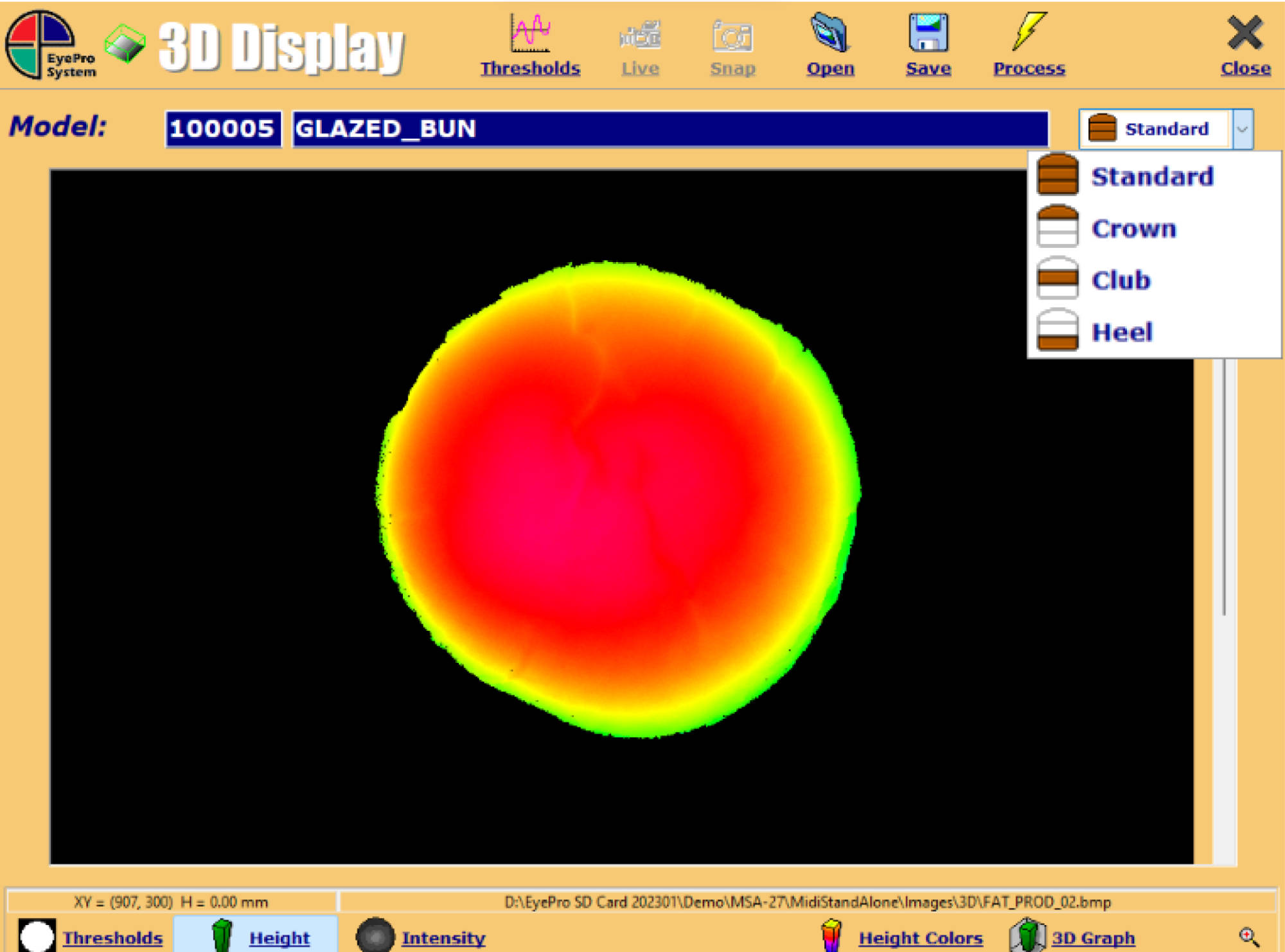

Product-Based Specification "Models"

Vision-based quality control systems recognize and analyze many attributes simultaneously for each product that passes under the system. These attributes, such as size, shape, and color, for example, are inspected for any deviations from your established quality specifications and, if a product doesn’t meet those criteria, rules are engaged to instruct the system how to handle that product. This is what we refer to as the Product Model, and it is the information from the model that enables the automated inspection process. A product model is created for each type of product (e.g. glazed bun, baguette, donut, etc.) you want to measure.

Automate Production Sampling

- Measure products from one or multiple lines in a facility

- Product is put on conveyor and measurements are automatically collected

- Measurements are consistent and independent of operators skill level (compared to training an operator to use a calliper or colorimeter)

- Quicker collection of data

Measure and Profile New Products

- Objective measurements

- Images of products can be saved

- Data can be collected and statistics calculated and reported

- Measurements can be collected for baked and unbaked products and data correlated

System Components

- Stand Alone System

- Color Camera

- 3D Camera

- Plastic Modular Belt

- Mounted on locking wheels for portability

- Scale can be provided as an option and integrated so weights included in data

- Data Collected and Statistics available in reporting capability

Measurements

The TheiaVu® E-Series offers comprehensive measurements on most bakery products.

VISION INSPECTION & MEASUREMENT CAPABILITIES

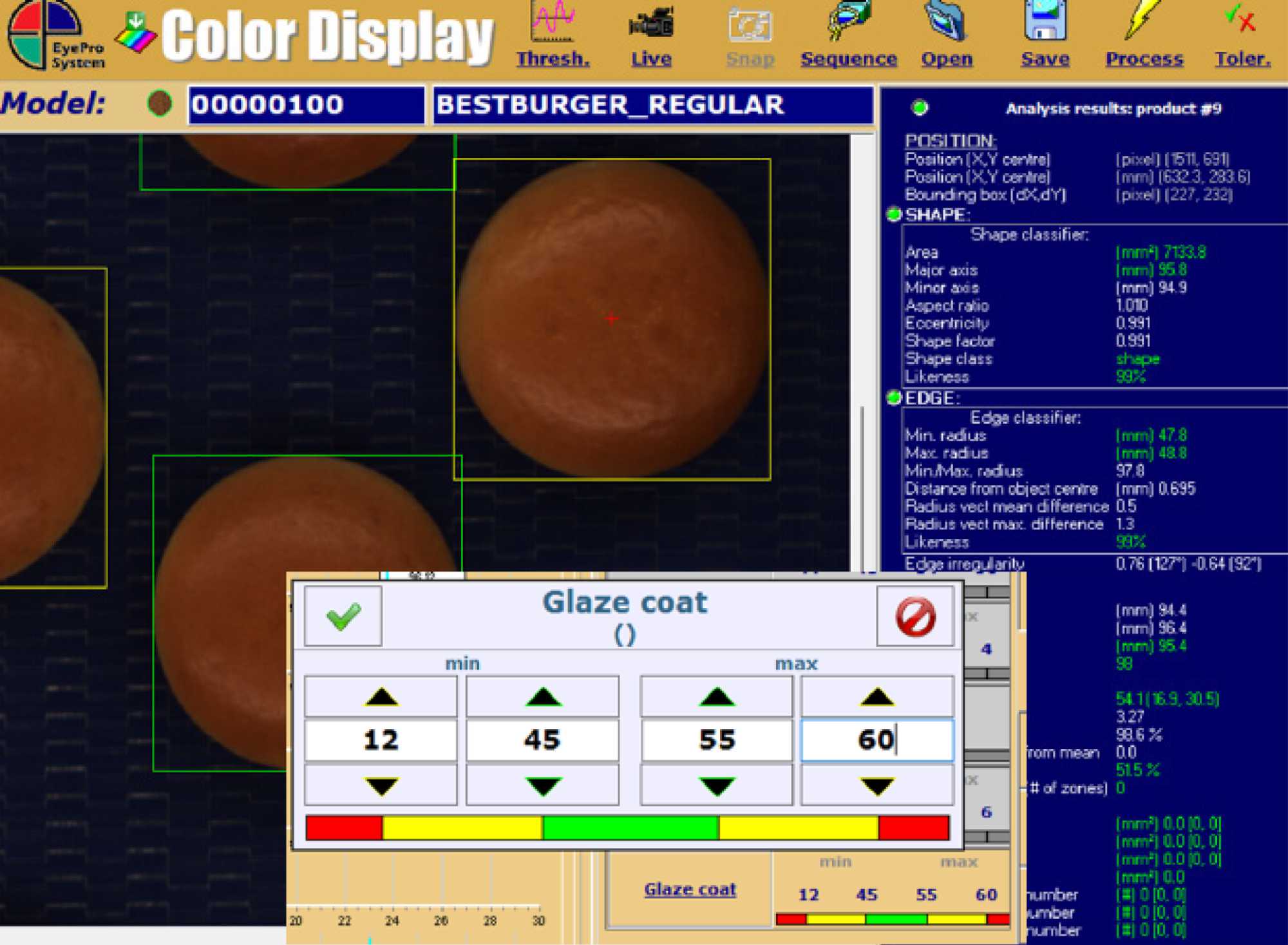

TheiaVu® E-Series is able to measure and inspect numerous product features, including 2D/Shape & Size, 3D/Height, Color and Surface Attributes. A set of parameters, specific for each product type, are collected by the System, providing the customer with a full set of information regarding the top and bottom of the product.

Below is an example of inspection, image processing and rejection of hamburger buns:

TheiaVu® E-Series is able to measure and inspect numerous product features, including 2D/Shape & Size, 3D/Height, Color and Surface Attributes. A set of parameters, specific for each product type, are collected by the System, providing the customer with a full set of information regarding the top and bottom of the product.

Below is an example of inspection, image processing and rejection of hamburger buns:

Software

POWERFUL AND EASY TO USE BAKESPECT™ SOFTWARE

BakeSpect™ software is easy to use and can be configured to include advanced measurements such as glaze and uses artificial intelligence (AI) for automatic learning of shape and/or color of your products. These features and others help continually improve the functionality of the TheiaVu® E-Series system. The software simplifies the inspection process — from product set-up and real-time inspection, to process monitoring and quality analytics applications.

Specifications

Resources

We've highlighted a few knowledge center resources here to help you understand the product better. Please also visit our Knowledge Center for additional information and downloads, and don't forget that our team is always happy to answer any questions you have.